Advancing Sustainability and Operational Efficiency in Healthcare

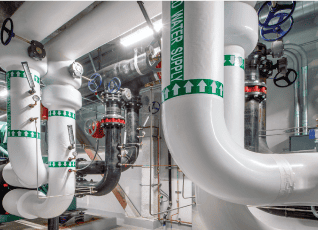

Water systems are critical to healthcare operations, but they also present significant challenges that affect energy use, infrastructure, and equipment performance. Issues like sediment buildup, biofilm formation, and poor system balance can drive up costs, waste energy, and compromise long-term sustainability. By addressing these challenges proactively, hospitals can improve efficiency, reduce expenses, and extend the lifespan of essential systems and equipment. Reducing energy waste Healthcare facilities rank among the most energy-intensive building types, with roughly 42.3% of their energy usage tied to reheating processes. Inefficient water systems—whether due to sediment buildup, poor insulation, or imbalanced flow—force pumps, boilers, and reheaters to work overtime. This increased workload leads to higher operating costs and strains organizational efforts to meet sustainability targets. By focusing on improvements in water quality and system design, hospitals can reduce energy consumption, cut costs, and extend the life of vital equipment. Key strategies include: Implementing sustainable water treatment technologies Advanced technologies that reduce contaminants and pathogens in building water improve safety, extend the lifespan of plumbing systems, and reduce the frequency of repairs, which helps conserve resources and reduce waste. Leveraging smart monitoring technologies Real-time monitoring tools have revolutionized water management strategies in healthcare. Smart sensors and remote monitoring technologies allow facilities to proactively identify and address inefficiencies, reduce waste, and maintain optimal conditions for patient care. Protecting water infrastructure for long-term sustainability Protecting the longevity of plumbing systems and water-bearing equipment is an often overlooked aspect of water management that significantly impacts sustainability. By preventing damage caused by sediment, corrosion, and scale, businesses can reduce the need for frequent repairs and replacements, lowering waste and extending the lifespan of their infrastructure. Supporting broader sustainability initiatives Water management is essential for organizations aiming to meet their broader sustainability objectives. Enhancing the efficiency of water infrastructure, reducing energy consumption, and adopting environmentally friendly water treatment technologies align with environmental, social, and governance goals. By leveraging advanced technologies and real-time monitoring, businesses can optimize water use, cut energy costs, conserve resources, and reduce carbon footprints, driving meaningful progress toward a sustainable future. Ready to get started? Contact LiquiTech today for a water management analysis to see how you can take your sustainability efforts to the next level.

Smarter Water Management with LiquiTech™ Smart Sensors

Building water systems are complex, comprising networks of pipes, valves, and equipment that must function seamlessly to ensure safety, efficiency, and compliance. This complexity often hides critical issues—from unbalanced systems and equipment inefficiencies to risks of bacterial growth and scald risks. With LiquiTech™ Smart Sensors, you can uncover these hidden issues and take control of your water management like never before. LiquiTech Smart Sensors combine advanced sensing technology, powerful analytics, and real-time monitoring to simplify the complexity of managing building water systems. By providing actionable insights and predictive capabilities, they empower you to enhance system performance, reduce risks, and lower costs. Continuous monitoring for real-time insights LiquiTech Smart Sensors provide 24/7 visibility into your water system’s performance by monitoring key parameters such as temperature and flow. This real-time data enables you to quickly detect anomalies, maintain system health, and ensure reliable operation. Data-driven decision making LiquiTech Smart Sensors connect to a secure cloud-based platform to deliver detailed analytics and reporting. This transforms raw data into actionable insights, helping you identify trends, address inefficiencies, and make informed decisions to improve your water system. Advanced risk detection Prevent issues before they occur. Our smart sensors detect conditions that may lead to bacterial growth, equipment failures, or energy inefficiencies. With early warning capabilities, you can address risks proactively, ensuring a safer environment for building occupants. Optimize energy and operational efficiency Reduce energy consumption and operational costs with LiquiTech Smart Sensors. They highlight inefficiencies such as unbalanced systems or inadequate insulation, allowing for targeted interventions that improve performance and lower expenses. Streamline compliance and reporting LiquiTech Smart Sensors automate routine temperature checks and provide comprehensive reports, simplifying compliance and reducing manual effort so you can focus on actionable insights that improve water safety. Seamless integration and installation Designed for convenience, LiquiTech Smart Sensors are non-invasive and easy to install. They attach externally to existing infrastructure without requiring disruptive plumbing modifications and integrate seamlessly with Building Management Systems (BMS). Unlock the potential of advanced water intelligence LiquiTech Smart Sensors empower you to transform how you manage your water system. By combining advanced technology, real-time data, and actionable insights, our solution delivers superior performance, improved safety, and cost savings. Experience smarter water management today. Contact LiquiTech to learn how our Smart Sensors can make your water system more intelligent.

AAMI ST108: Ensuring Water Quality in Medical Device Processing

The Association for the Advancement of Medical Instrumentation (AAMI) introduced Standard ST108 in 2023 to replace the previous AAMI TIR34:2014/(R)2021 standard. AAMI ST108 includes guidelines on: Categories of water quality: Defines water quality requirements for each stage of sterile processing. Water quality monitoring: Sets criteria for assessing water quality, including turbidity, pH, microbial levels, conductivity, and other factors. Water treatment: Establishes protocols for maintenance, monitoring, and quality improvement in water treatment systems. AAMI ST108 is considered a best practice for patient safety and is likely to become a requirement of other standards, like The Joint Commission Water Management Standard EC.02.05.02. Categories of water quality AAMI ST108 standardizes water quality for medical device processing to prevent adverse outcomes associated with substandard water. It defines three primary water quality levels—utility, critical, and steam—each tailored to different stages of device sterilization and disinfection. Utility water or tap water is generally minimally processed and used for tasks like flushing and washing. Critical water requires higher purity levels for tasks like high-level disinfection and final rinsing. Steam is used in sterilization and must meet specific standards to ensure safety and efficacy. The standard includes extensive testing protocols to ensure water quality across these categories. Key testing criteria include turbidity, pH, microbial levels, conductivity, and various chemical parameters. Water quality monitoring To comply with ST108, facilities must routinely test utility, steam, and critical water to ensure consistent quality. Water testing should cover microbial and chemical parameters as well as general water quality metrics like turbidity, pH, and total organic carbon. Routine testing frequency is determined based on initial validations and risk assessments, with periodic testing following interruptions, repairs, water advisories, or in response to adverse outcomes (e.g., staining, discoloration, or deposits on medical equipment). Facilities should create sample locations representative of water contact points and monitor this over time to ensure ongoing compliance with ST108 standards. All water quality parameters, monitoring and verification protocols, and control measures should be incorporated into the facility’s existing water management plan. Water treatment In the ST108 sterilization process, water treatment is divided into three main stages: pretreatment, primary treatment, and storage/distribution/final treatment. Each stage is essential in preparing high-purity, sterile water for medical and sterilization equipment. Here’s a breakdown of how these stages are structured. Stage 1: Pretreatment The pretreatment stage prepares water for further purification. This step ensures that downstream equipment operates efficiently by removing larger particles, sediments, chlorine, and hardness, which could cause damage or interfere with subsequent treatments. Sediment filtration: Filters particles and sediment from the utility water that could harbor bacteria or clog and damage equipment. Carbon filtration: Dechlorinates water by removing chlorine and organic compounds. Water softening: Reduces hardness (calcium and magnesium) to prevent scaling and extend equipment life. Stage 2: Primary treatment The primary treatment stage refines water quality to meet strict purity and safety standards, making it suitable for medical sterilization applications. The goal of this stage is to achieve high levels of purity by removing dissolved ions, organic contaminants, and microorganisms. Reverse osmosis (RO): Uses a semipermeable membrane to filter out ions, organic matter, and some microorganisms, creating purified water. Deionization (DI): Uses ion-exchange resins to further purify the water by removing any remaining dissolved salts and ions. Stage 3: Storage, distribution, and final treatment This stage maintains water quality during storage and distribution and ensures the highest purity right before use. The purpose of this stage is to prevent microbial contamination and ensure that water remains sterile at the point of use. UV disinfection: Provides final microbial inactivation by using UV light to disrupt bacterial DNA. Point-of-use filtration: Use of micropore or ultrafine filters at the final outlet to prevent contaminants from entering the sterilization cycle. Incorporating ST108 into your water management program To incorporate ST108 into your water management plan, start by reviewing your current water treatment processes and identifying areas that need alignment with ST108’s requirements. Involve key personnel such as facility managers, infection preventionists, clinical engineering staff, medical device processing personnel, and water safety specialists who understand both operational needs and regulatory standards. These specialists will assess your existing setup, identify gaps, and update treatment protocols to ensure compliance. Collaborate with water treatment experts to implement technologies that meet ST108 criteria at each stage of water handling, from pretreatment to storage and distribution. For example, they may recommend sediment filtration, softening, or UV disinfection systems tailored to your facility’s usage patterns and contaminant profile. Additionally, integrate regular testing and monitoring into your water management plan to ensure ongoing compliance and make adjustments to processes as needed. Partnering with LiquiTech to comply with ST108 LiquiTech simplifies ST108 compliance with targeted solutions that streamline water quality monitoring and control. Water quality testing facilitation Coordination services to streamline ST108 testing compliance. Automatic shipment of sampling bottles and coordination with third-party labs. Water management program integration Support in incorporating ST108 guidelines into your water management plan. LiquiTech™ Sediment Filtration (pretreatment) Removes particulates from utility water to meet ST108 standards, making it suitable for critical applications. Protects reverse osmosis (RO) and deionization (DI) systems by reducing fouling and scaling, which extends equipment lifespan and lowers maintenance costs. Minimizes biofilm formation to reduce microbial risks. Ready to get started? Contact LiquiTech today to see how we can help your facility comply with AAMI ST108.

Why Legionella Isn’t Just a Hot Water Problem: Risks in Cold Water

Legionella is a waterborne pathogen that contaminates nearly half of all building water systems. It typically enters through the municipal cold water supply and thrives in areas of the water system with sediment accumulation, stagnant water, warm temperatures, or where other microbes are present. While hot water is often seen as the biggest risk for Legionella growth, cold water systems can also harbor the bacteria, making it a hidden threat in many buildings. Legionella in hot water systems Potable hot water systems, particularly untreated ones, can act as major reservoirs for Legionella growth. The most suitable temperature for Legionella growth is between 90°F and 120°F, making hot water systems a high-risk environment for Legionella. Legionella in cold water systems Legionella can survive in water temperatures below 77°F, making cold water systems susceptible to colonization. In fact, a research article published by the CDC found as many as 47% of surveyed cold water taps were positive for Legionella. Although cold water systems typically present less favorable conditions for Legionella growth compared to hot water systems, certain factors—such as elevated cold water temperatures and high sediment levels—can create an environment conducive to its survival. In warmer regions where cold water temperatures tend to be higher, the risk of Legionella colonization increases significantly. Legionella species in cold water Several types of Legionella can survive and grow in low temperatures, including Legionella pneumophila, the species responsible for most cases of Legionnaires’ disease in the United States. This strain prefers higher cold water temperatures, while other species like Legionella anisa and Legionella longbeachae tend to survive in colder environments. Although these non-pneumophila species are less likely to cause illness, they’ve been linked to outbreaks of Pontiac Fever. Controlling Legionella in cold water Effectively controlling Legionella in cold water systems requires a strategic approach that combines proven methods. The right solution will depend on factors like the level of contamination, the building’s location, and the vulnerability of its occupants, but a combination of the below water treatment technologies is typically recommended. By combining these solutions, you can significantly reduce the risk of Legionella in cold water systems. Copper-silver ionization, UV disinfection, and sediment filtration together offer a complete and proactive approach to creating safer and healthier environments in buildings. References Garner E, Brown CL, Schwake D, Rhoads WJ, Arango-Argoty G, Zhang L, et al. Comparison of Whole-Genome Sequences of Legionella pneumophila in Tap Water and in Clinical Strains, Flint, Michigan, USA, 2016. Emerg Infect Dis. 2019;25(11):2013-2020. https://doi.org/10.3201/eid2511.181032 Wadowsky, R. M., R. Wolford, A. M. McNamara, and R. B. Yee. 1986. Effect of temperature, pH, and oxygen level on the multiplication of naturally occurring Legionella pneumophila in potable water. Appl. Environ. Microbiol. 49:1197-1205. Rogers, J., A. B. Dowsett, P. J. Dennis, J. V. Lee, and C. W. Keevil. 1994. Influence of temperature and plumbing material selection on biofilm formation and growth of Legionella pneumophila in a model potable water system containing complex microbial flora. Appl. Environ. Microbiol. 60:1585–1592. Mauchline WS, James BW, Fitzgeorge RB, Dennis PJ, Keevil CW. Growth temperature reversibly modulates the virulence of Legionella pneumophila. Infect Immun. 1994 Jul;62(7):2995-7. Soderberg, M.A., Dao, J., Starkenburg, S.R., Cianciotto, N.P. 2008. Importance of type II secretion for the survival of Legionella pneumophila in tap water and in amoebae at low temperatures. Appl. Environ. Microbiol. 74(17):5583-5588. De Giglio, O., D’Ambrosio, M., Spagnuolo, V., Diella, G., Fasano, F., Leone, C. M., Lopuzzo, M., Trallo, V., Calia, C., Oliva, M., Pazzani, C., Iacumin, L., Barigelli, S., Petricciuolo, M., Federici, E., Lisena, F. P., Minicucci, A. M., & Montagna, M. T. 2023. Legionella anisa or Legionella bozemanii? Traditional and molecular techniques as support in the environmental surveillance of a hospital water network. Environmental monitoring and assessment, 195(4), 496.

CDC Report: Burkholderia multivorans Infections Linked to Hospital Ice Machines

A Centers for Disease Control and Prevention (CDC) report published on October 3, 2024, linked Burkholderia multivorans infections to ice machines in multiple healthcare facilities in the western United States. This post summarizes key findings, implications, and recommended practices for healthcare providers to ensure patient safety. Background Burkholderia multivorans, a member of the Burkholderia cepacia complex, is an opportunistic pathogen commonly found in soil and water. It poses a significant risk to immunocompromised patients, leading to severe infections. Previous outbreaks have linked this bacterium to contaminated medications and medical devices. However, a recent investigation linked the use of ice and water from ice machines in hospitals as a potential transmission route. Between 2021 and 2022, 23 cases of Burkholderia multivorans were reported at two hospitals in Southern California. Further investigations revealed an additional 23 previously unreported cases between 2020 and 2024 across various hospitals in California and Colorado. All affected facilities used the same brand of ice machines, filters, and cleaning products, suggesting a common source of contamination. Investigation findings The investigation defined cases as infections from the outbreak strain (ST659) of Burkholderia multivorans in patients without cystic fibrosis. A total of 46 cases were identified across four hospitals: Environmental sampling indicated that B. multivorans was isolated from ice machines at some of these hospitals, confirming the link between contaminated ice and clinical cases. Genomic testing revealed that the clinical and environmental isolates were genetically similar, with only minor variations. This reinforces the hypothesis that contaminated ice machines were a significant source of exposure for patients. Recommendations for healthcare facilities Given the serious nature of these findings, the report emphasizes the need for healthcare facilities to implement robust infection control measures. Key recommendations include: The association between Burkholderia multivorans infections and ice machines in healthcare settings underscores the critical need for vigilance in infection control practices. By taking proactive measures like implementing a comprehensive water management program and adopting building water treatment technologies, healthcare facilities can minimize the risk of contamination and protect vulnerable patients from serious infections.

Understanding the Impact of NJ Bill S2188 on Building Water Systems

On September 12, 2024, New Jersey passed Bill S2188, aimed at reducing the risk of Legionnaires’ disease. This law requires hospitals, nursing homes, high-rise residential buildings, senior housing, hotels, and other commercial and industrial spaces to establish water management programs to minimize the growth and spread of Legionella bacteria in building water systems. The bill also outlines specific requirements for the Department of Environmental Protection (DEP), Department of Health (DOH), and owners and operators of certain public community water systems. This article only covers the sections of the bill related to buildings. Which buildings are affected by NJ Bill S2188? Facilities covered by this legislation include: NJ Bill S2188 compliance requirements To meet the standards set by NJ Bill S2188, building owners and operators must take the following actions: Penalties for non-compliance Failure to comply with these regulations can result in fines: Partnering with LiquiTech to comply with NJ Bill S2188 NJ Bill S2188 requires strict water management to prevent Legionnaires’ disease. LiquiTech is here to help you meet these new standards. Our team specializes in water management and Legionella prevention, ensuring your building’s water systems are safe and fully compliant with the law. From creating your water management plan to providing ongoing support, we’re here to help you maintain a safe and healthy environment. Ready to get started? Contact LiquiTech today to see how we can help your facility comply with NJ Bill S2188 and protect your building’s occupants.

How Weather, Climate, and Water Sources Impact Waterborne Disease Hospitalizations

A recent study from Columbia University, published in the open-access journal PLOS Water, investigates how weather conditions, climate, and water sources affect hospital admissions for waterborne infectious diseases in the United States. The study examined 12 years of data from 516 hospitals in 25 states. Key findings on biofilm-forming bacteria Biofilm-forming pathogens, such as Legionella, Pseudomonas, and Nontuberculous mycobacteria (NTM), thrive in biofilms within water distribution systems and are responsible for respiratory infections, especially among vulnerable populations like individuals over 55 or those who are immunocompromised. During the study period, biofilm-forming bacteria were responsible for 81% of all waterborne disease hospitalizations. Geographical and environmental influences Conclusion The study identifies a clear link between meteorological conditions, drinking water sources, and hospitalization rates for waterborne diseases. With climate change potentially leading to more extreme weather events, the study highlights the need for improved water infrastructure and water management practices to mitigate the risk of these waterborne infections, particularly in urban areas and regions dependent on groundwater sources.

Plumbing 201 for Infection Preventionists: The Impact of Plumbing on Healthcare

Healthcare facilities are tasked with preventing the spread of healthcare-associated infections (HAIs), and the intricacies of plumbing design and material selection play a significant role in this effort. The role of biofilm in promoting bacteria and pathogens in healthcare water systems including drains and the link between drinking water outbreaks like Legionella to biofilm in plumbing systems, and the importance of selecting the right materials for supply lines are all pivotal in curbing the risk of HAIs. The role of plumbing in infection control Understanding the interaction between plumbing materials and microbial growth is imperative for Infection Preventionists (IPs). Making informed choices during construction and renovation allows for the selection of materials that not only minimize infection risks but also ensure compliance with health and safety standards. By collaborating effectively with facility management, IPs can significantly contribute to joint infection control initiatives, ensuring that plumbing systems do not become a source of infection. Key plumbing terms to understand Infection prevention requires a firm grasp of key plumbing concepts that impact patient safety. Understanding terms such as leaching, corrosion, and biofilms enriches an IP’s toolkit, allowing for better mitigation of risks associated with waterborne infections. Leaching The process by which materials, such as metals or chemicals, dissolve or are washed out from the pipe material into the water due to contact with the water over time. In healthcare settings, leaching can introduce potentially harmful substances into the water supply, affecting water quality and patient safety. Corrosion The gradual destruction or deterioration of materials (metals, alloys, plastics, etc.) caused by chemical reactions with their environment. In pipes, corrosion can lead to reduced water flow, leaks, and the release of metals into the water, which can serve as nutrients for microbial growth, including biofilms. Biofilm A complex aggregation of microorganisms, including bacteria, fungi, and protozoa, that adhere to each other and surfaces, encased in a protective and adhesive matrix. Biofilms in plumbing systems can harbor pathogens, making them resistant to disinfection and posing a significant risk for HAIs. Types of lines: Supply, return, drain, waste Plumbing systems consist of multiple types of lines, each with a distinct function. Here, we explore supply lines, return lines, drain lines, and waste lines. Grasping the role of each type is vital for maintaining an efficient, safe, and reliable plumbing system. Supply lines The integrity of plumbing supply lines is critical in delivering safe, potable water for drinking, handwashing, and patient care activities. Materials like copper, PEX, and CPVC are chosen for their durability and reliability. Flexible water supply pipes offer installation ease and adaptability, making them an excellent choice for connecting water supplies to fixtures in constrained spaces. Their construction from materials like stainless steel, PVC, or braided nylon offers durability and resistance to corrosion, ensuring reliable performance over time. Return lines Equally important are the plumbing return lines, which ensure the efficient operation and delivery of potable water systems. They contribute to patient comfort and infection control by reducing water age and stagnant conditions, preventing sediment accumulation, and ensuring temperature and disinfectant residuals. Drain and waste lines Proper sanitation in healthcare facilities hinges on effectively removing wastewater and materials through well-designed drain and waste lines. Choosing the right materials, such as PVC or cast iron, and ensuring their correct installation and maintenance are key factors in preventing backflows and the spread of pathogens. Types of plumbing material and their impact on patient safety Exploring the benefits and potential risks associated with commonly used plumbing materials—including copper, stainless steel, cast iron, galvanized steel, and various plastics such as PVC, CPVC, and PEX—helps IPs make informed decisions. PVC, CPVC, and PEX are generally not used in healthcare plumbing due to their susceptibility to biofilm formation and potential chemical leaching. These materials can create environments conducive to microbial growth, posing significant infection risks in healthcare settings. Additionally, their lower thermal tolerance and potential for chemical degradation under high-temperature water systems make them less suitable for the stringent plumbing requirements in healthcare facilities. Each material has its advantages, such as antimicrobial properties or corrosion resistance, but also considerations like the need for regular maintenance to prevent contamination. Copper Copper is favored for healthcare plumbing because of its antimicrobial qualities and durability. It lowers microbial levels in water systems and keeps water quality high with a lower risk of contamination, however over time, it can lose these properties due to scale and sediment accumulation. Used in drinkable water lines, both hot and cold, copper helps reduce infections associated with healthcare. Regular checks and maintenance are needed to avoid bacterial contamination from damaged pipes. Despite its initial cost, copper’s health advantages and long-term use can make it a cost-effective choice. Stainless steel Stainless steel is favored in healthcare for its corrosion resistance, hygiene, and durability. Its non-porous surface helps reduce bacterial growth and biofilm, promoting a cleaner water supply and helping prevent HAIs. Despite higher initial costs, its longevity and minimal replacement needs make it a cost-effective choice. Regular maintenance, including inspections and proper cleaning, is crucial for its long-term use. Stainless steel plays a vital role in maintaining patient safety in healthcare settings. Cast iron Cast iron pipes, commonly used for underground plumbing due to their durability and sound-dampening qualities, are mainly used in drainage and vent systems. Over time, these pipes may corrode, risking water contamination and health hazards. Therefore, regular checks and upkeep are crucial. Despite potential risks, when well-maintained, cast iron pipes remain a good choice for healthcare facilities, offering high crush strength and noise reduction, which is important for patient comfort. Prioritizing patient safety in healthcare plumbing material selection is key. Galvanized steel Once popular for their corrosion resistance, galvanized steel pipes can degrade over time. The zinc coating may wear off, leading to rust and bacterial growth. In healthcare settings, these pipes are unsuitable for drinking water systems due to potential water quality issues and health risks. Modern facilities prefer safer materials to reduce risks. Regular maintenance, including corrosion checks, water tests for

Plumbing 101 for Healthcare Infection Preventionists

As an infection preventionist, ensuring patient safety is a top priority. Access to clean and safe drinking water is crucial throughout patient care, making plumbing a critical component in maintaining a safe healthcare environment. In this blog, we will discuss the importance of plumbing in infection prevention, plumbing equipment associated with increased infection risk, and strategies to mitigate these risks. Common plumbing equipment in healthcare Water-bearing equipment can pose infection risks if not properly designed, maintained, and monitored. Infection preventionists should collaborate with facility staff to ensure the regular inspection and maintenance of valves and other plumbing equipment to minimize potential biofilm formation, water stagnation, and other infection risks and incorporate these activities into water management programs. Common plumbing infrastructure in healthcare facilities that can increase infection risk, include: Valves Plumbing valves such as gate valves and check valves regulate water flow and prevent backflow. They play a crucial role in controlling the direction and rate of water flow within a plumbing system. However, if not correctly sealed and maintained, valves can allow contaminants to enter the water system. They can also harbor pathogens within the biofilms that form on their inner surfaces, further increasing the risk of contaminants being introduced into the water. Valves should be regularly maintained and inspected for deficiencies to ensure proper operation. Recirculation pumps Recirculation pumps are devices used in plumbing systems to circulate hot water throughout a building. They play a key role in providing hot water quickly and efficiently to all outlets in the building. However, if not sized, installed, or maintained properly, recirculation pumps may increase the risk of infections by contributing to a favorable environment for pathogen growth. Storage tanks and water heaters Storage tanks and water heaters are crucial components of water plumbing systems, used to store and heat water for various purposes such as bathing, washing, and cooking. They are designed to maintain a steady supply of hot water at all times, ensuring convenience for the users. Tanks and heaters can harbor and contribute to pathogen growth by providing a warm water environment. This can be compounded through configurations that may lead to sediment accumulation, stagnant conditions, and temperature stratification. They pose additional risks such as leaks and corrosion if not maintained properly Water softeners Water softeners are devices designed to remove minerals such as calcium and magnesium from hard water. The purpose of using water softeners in building water plumbing systems is to prevent mineral buildup in pipes and appliances, which can reduce their efficiency and lifespan. However, water softeners may increase the risk of infections by creating an environment that promotes the growth of bacteria and other microorganisms within the water softener. If softeners are not planned or designed properly, they can also reduce disinfectant residuals, further increasing the risk of waterborne pathogens. Dead legs in pipes Dead legs in plumbing pipes are sections of pipe that do not experience sufficient flow or use. These stagnant areas of water can become breeding grounds for harmful bacteria, such as Legionella. If not effectively managed, dead legs can pose a health risk to building occupants and compromise the overall quality of the water system. Cross connection in pipes Cross connections in pipes occur when two different plumbing systems, such as a drinking water system and a non-potable water system or between the hot water system and cold water system, are connected by a common pipe. However, cross connections can pose a serious risk to building water plumbing systems by allowing water to flow between the two systems which can impact temperature delivery, disinfectant residuals, sediment levels, and even contamination of waterborne pathogens, potentially causing illness for those who consume it. Strategies for infection prevention There are various strategies to prevent infections when it comes to water-bearing equipment. All these elements above should be incorporated in the facility’s water management program, to provide a legally defensible program to mitigate the risk of waterborne pathogens. Understanding the importance of plumbing in healthcare settings is critical to preventing the spread of infections. By implementing the strategies discussed in this blog, you can help mitigate plumbing-related infection risks and foster a safe healthcare environment. Plumbing 101 group training Are you interested in a comprehensive plumbing training? LiquiTech’s group training sessions elevate your team’s knowledge, improve your water management practices, and offer the ability to earn continuing education credits, if applicable. Request the Plumbing 101 for Infection Preventionists training today.

Legionella: What Is It and How to Control It

What is Legionella? Legionella is a bacterium that causes Legionnaires’ disease and Pontiac fever. It was named after the first known outbreak of Legionnaires’ disease in 1976 at an American Legion Convention. Legionnaires’ disease is a severe type of pneumonia. Pontiac fever is a less severe illness that typically resolves without hospitalization. Approximately 90% of Legionnaires’ disease cases are caused by Legionella pneumophila. Non-pneumophila species are responsible for fewer than 10% of cases. Where is it found? Legionella can be found in natural water sources. It can survive traditional municipal water treatment processes and be distributed to buildings from the municipal water supply. Once in building water systems, ideal conditions, like warm water, sediment, and other microorganisms, can cause it to proliferate. Potable water systems, especially hot water systems, are the highest concern for Legionella growth and transmission. High-risk non-potable systems include cooling towers, decorative water features, whirlpools, spas, and misters. More than half of outbreaks occur in healthcare facilities. Outbreaks have also been linked to nursing homes, hotels, workplaces, apartment complexes, and community sources. What are the health concerns? Legionnaires’ disease can be contracted through exposure to contaminated water, usually via inhalation of aerosolized particles or aspiration. Cases have also been linked to direct installation, such as nasogastric tubes. People with weakened immune systems, chronic lung disease, diabetes, cancer, transplants, steroid use, and the elderly are at higher risk of contracting the disease. However, roughly 25% of cases have no known risk factors. More than 95% of cases require hospitalization, and more than 30% require admission to the ICU. The disease fatality rate is over 10%. Healthcare facilities are the most common exposure setting, accounting for 57% of cases and 85% of deaths. How can Legionella be controlled? There are many strategies to reduce Legionella risk in building water systems. To start, Legionella testing should be conducted to identify if and where Legionella is present in the water system so evidence-based remediation strategies can be implemented. Continuous supplemental disinfection can be installed to remediate the entire water system and provide long-term Legionella control. The most effective is copper-silver ionization. It is highly effective against Legionella and other waterborne pathogens and does not have any negative side effects, like corrosion or harmful disinfection byproducts. Short-term remediation options, like chlorine shock treatments, have varying efficacy. If Legionella reduction is achieved, it is typically short-lived. Point-of-use filters can be installed on faucets, showerheads, and ice machines to prevent exposure to Legionella and other waterborne pathogens. However, they do not remediate the water system and require ongoing maintenance and costs, so they are usually deployed temporarily or in high-risk units. Engineering controls like circulation, flushing, and temperature can prevent favorable conditions but do not fully mitigate risk. These controls should be used in conjunction with other strategies. A water management plan and routine Legionella testing should be utilized to help evaluate and manage ongoing Legionella risks in building water systems. Download: Legionella fact sheet Fill out the form below to download our Legionella fact sheet to keep on hand or to share with your team.