What is corrosion?

Corrosion is the degradation or deterioration of a material caused by a reaction to its environment. In building plumbing systems, corrosion can occur in our piping systems and water-bearing equipment due to reactions, chemicals, and impurities in the water.

These processes result in uniform corrosion, pitting, cracking, or erosion, ultimately causing the breakdown and failure of the piping system and components.

How does it impact plumbing?

Corrosion significantly impacts the plumbing system, operations, maintenance, costs, and equipment. It can lead to pinhole leaks in the piping and pipe blowouts, which can ultimately cause water damage to the surrounding area. Corrosion can also cause loss of efficiency, reduction in performance, blockages, and total equipment failure of valves, pipes, pumps, and heaters.

All corrosion impacts have significant financial consequences, including pipe and equipment replacement, labor for repairs, maintenance and system interruptions, and downtime.

What causes it?

The corrosivity and corrosion rate of our building’s water systems depends on several water characteristics, including sediment levels, flow, temperature, chemical treatment programs, and microbial communities.

- Sediment levels: High sediment levels or sediment accumulation over time can cause wear and tear on plumbing components and piping.

- Flow rate: Flow rate can also impact the corrosion potential, with high flow rates increasing the erosion of plumbing materials and low flow rates leading to sediment accumulation and a higher potential for pitting.

- Water temperature: Water temperature is a significant contributor to corrosion, with the corrosion potential and rate increasing three to four times from a water temperature of 60°F to 140°F.

- Chemical treatment: Chlorine-based water treatment methods like chlorine, chlorine dioxide, and monochloramine can be corrosive due to chemical reactions with plumbing materials.

- Microbial communities: Microbes in our water system can lead to microbially induced corrosion (MIC), with several categories of MIC, including acid-producing, iron-related, slime-forming, and sulfate-reducing. These microorganisms can eat away at plumbing materials for nutrients or produce corrosive compounds that degrade equipment, such as hydrogen sulfide.

How can it be controlled?

Avoiding corrosive water treatment methods, such as chlorine, chlorine dioxide, and monochloramine, will significantly impact the life of plumbing systems. An alternative technology, copper-silver ionization, has greater efficacy against waterborne pathogens and does not increase the corrosivity of the water system.

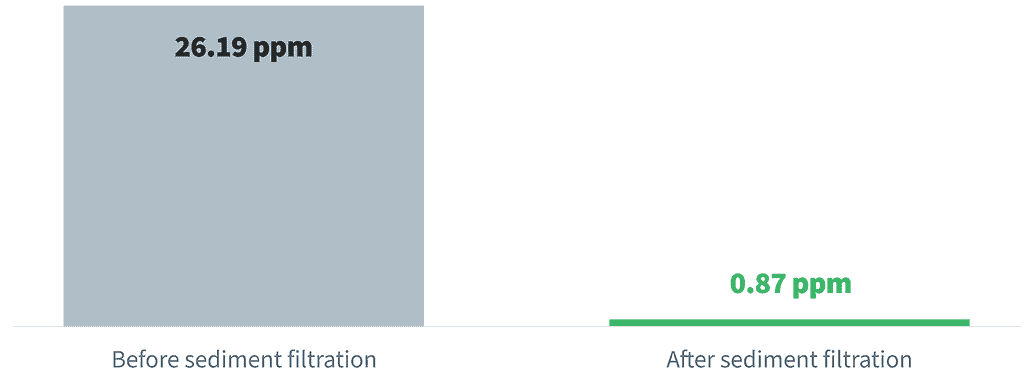

Installing a sediment filtration system on the incoming water supply will significantly reduce the amount of sediment entering the building water system. This protects the water system from sediment accumulation, which can lead to corrosion of equipment and pipes. The filtration system will also protect against external disruptions or surges in sediment, which can build up in a system, erode equipment, and impact equipment life.

Case study: Colorado hospital sediment filtration success story

Sediment in the incoming water supply caused pinhole leaks, forcing the replacement of two-year-old piping for $80K. Installing a LiquiTech™ Sediment Filtration System reduced sediment entering the building’s water system. Read the full case study here.

Sediment levels (96.7% reduction)

Download: corrosion fact sheet

Fill out the form below to download our corrosion fact sheet to keep on hand or to share with your team.