Copper-Silver Ionization: A Simple and Effective Solution for Legionella Remediation

Legionella remediations are treatment processes for controlling Legionella in a building water system, generally deployed after routine Legionella testing returns shows systemic positivity or if a case of Legionnaire’s disease is traced back to the facility. Copper-silver ionization is a proven remedial water treatment method backed by hundreds of independent research studies. It’s simple, effective, and provides many advantages over other remedial treatments, including: Quick control of Legionella Copper-silver ionization is a highly effective and efficient method for controlling Legionella, typically achieving system-wide control within days. Other short course remediations include shock disinfections, such as hyperchlorination or superheat and flushes. These procedures may not always be effective and generally require multiple treatments to control Legionella. When they are effective, reduction of Legionella is temporary, and positivity typically returns within weeks. In fact, the superheat and flush method is no longer a recommended option for remediation due to failure to control Legionella. Case studies Less disruptive Copper-silver ionization is less disruptive than superheat and flush and shock treatments with chlorine, monochloramine, or chlorine dioxide. No plumbing damage or corrosion Copper-silver ionization does not damage plumbing and is non-corrosive. Shock treatments, such as hyperchlorination, significantly impact plumbing, corroding pipes, heaters, pumps, valves, and other plumbing equipment. Monochloramine treatments damage rubber fittings and are more corrosive to metals than copper-silver ionization. Long-term infrastructure impacts after shock treatments include equipment wearing out faster and requiring more maintenance and more frequent servicing. Equipment may fail prematurely, resulting in unplanned equipment replacement costs. Achieves long-term control Copper-silver ionization provides long-term control of Legionella and other waterborne pathogens. For temporary installations, it can provide up to three months of residual protection after the equipment is turned off. For permanent installations, it protects for as long as the system is operating and maintained. More cost-effective Copper-silver ionization is generally more cost-effective over the long term than shock treatments with chlorine or chlorine dioxide. Both methods typically require three or more treatments and can take months or years to gain control. Copper-silver ionization can achieve control in a few days and continuously treats the water if installed and maintained, so it does not require multiple treatments. Superheat and flush require heating the hot water from around 120 degrees Fahrenheit to 160 degrees Fahrenheit, resulting in increased energy usage and costs. Copper-silver ionization is effective at all temperatures and does not require superheating the water, providing energy efficiency advantages over the superheat and flush method. Retrofits into existing plumbing Copper-silver ionization can be retrofitted into existing plumbing and mechanical rooms. For temporary installations or less complex plumbing systems, a portable unit can be used. The portable unit ports into the building’s existing plumbing infrastructure, so it requires little to no plumbing work. For permanent installations or more complex plumbing systems, a plumbed-in or racked unit is typically recommended. These units can be retrofitted into the existing plumbing infrastructure with minimal plumbing work. Point-of-use filters can be provided within 48 hours to provide immediate protection while the copper-silver ionization system is installed, and remediation efforts are underway. Provides precise control Copper-silver ionization provides real-time, precise control. It has a flow meter for proportional dosing, which allows for adjustments to ion output based on actual water usage. The system is also equipped with a remote monitoring system, which provides real-time data and rapid deployment of remote system adjustments based on current conditions. Copper-silver ionization is a simple and effective solution for remedial water treatment. It provides quick control of Legionella, can be retrofitted into existing plumbing, is less disruptive, provides long-term control, does not damage plumbing, and provides more precise control. It is essential to choose a company with expertise, experience, and ASSE 12080 certification that can help with Legionella remediation. Download: copper-silver ionization brochure If you need Legionella remediation and are interested in learning more about the LiquiTech™ Copper-Silver Ionization System, fill out the form below to download our product brochure to see how the technology works and view product specifications.

Safeguarding Hospital Infrastructure: A Colorado Hospital Sediment Filtration Success Story

A newly constructed hospital in Colorado encountered challenges immediately after its opening in 2016. Continuous pinhole leaks in the pipes arose due to sediment buildup issues. The high sediment loads in the incoming water supply caused pinhole leaks throughout different sections of pipe. As a result, the hospital had to replace pipes that should last a lifetime only after a few years which incurred an unbudgeted significant capital cost of over $80K. The hospital partnered with LiquiTech and installed a LiquiTech™ Sediment Filtration System on the incoming water supply. This system effectively reduced the amount of sediment entering the building, preventing further damage to the plumbing infrastructure and the newly installed pipe. As a result, the incoming sediment was reduced by more than 96%. This not only improved the water quality in the hospital but also minimized the risk of bacterial growth, such as Legionella. Additionally, it reduced maintenance time and costs, while extending the lifespan of the pipes and equipment. The Facilities Director expressed their satisfaction, stating, “The new Sediment Filtration System is easy to use and requires minimal maintenance. It is self-cleaning and has already extended the lifespan of our pipes.” By making this investment, the hospital successfully protected its infrastructure, enhanced water quality, and achieved significant cost savings. For more details on this success story, read the full case study here.

Corrosion: What Is It and How to Control It

What is corrosion? Corrosion is the degradation or deterioration of a material caused by a reaction to its environment. In building plumbing systems, corrosion can occur in our piping systems and water-bearing equipment due to reactions, chemicals, and impurities in the water. These processes result in uniform corrosion, pitting, cracking, or erosion, ultimately causing the breakdown and failure of the piping system and components. How does it impact plumbing? Corrosion significantly impacts the plumbing system, operations, maintenance, costs, and equipment. It can lead to pinhole leaks in the piping and pipe blowouts, which can ultimately cause water damage to the surrounding area. Corrosion can also cause loss of efficiency, reduction in performance, blockages, and total equipment failure of valves, pipes, pumps, and heaters. All corrosion impacts have significant financial consequences, including pipe and equipment replacement, labor for repairs, maintenance and system interruptions, and downtime. What causes it? The corrosivity and corrosion rate of our building’s water systems depends on several water characteristics, including sediment levels, flow, temperature, chemical treatment programs, and microbial communities. How can it be controlled? Avoiding corrosive water treatment methods, such as chlorine, chlorine dioxide, and monochloramine, will significantly impact the life of plumbing systems. An alternative technology, copper-silver ionization, has greater efficacy against waterborne pathogens and does not increase the corrosivity of the water system. Installing a sediment filtration system on the incoming water supply will significantly reduce the amount of sediment entering the building water system. This protects the water system from sediment accumulation, which can lead to corrosion of equipment and pipes. The filtration system will also protect against external disruptions or surges in sediment, which can build up in a system, erode equipment, and impact equipment life. Case study: Colorado hospital sediment filtration success story Sediment in the incoming water supply caused pinhole leaks, forcing the replacement of two-year-old piping for $80K. Installing a LiquiTech™ Sediment Filtration System reduced sediment entering the building’s water system. Read the full case study here. Sediment levels (96.7% reduction) Download: corrosion fact sheet Fill out the form below to download our corrosion fact sheet to keep on hand or to share with your team.

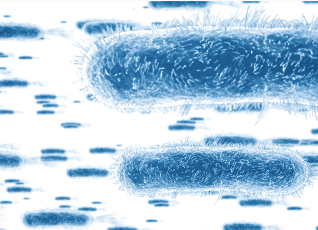

Biofilm: What Is It and How to Control It

Biofilms, intricate communities of microorganisms including bacteria, fungi, and other microscopic entities, thrive on surfaces through a remarkable process of collaboration and self-protection. Encased within a self-produced, slime-like matrix, these microorganisms firmly anchor themselves to a variety of surfaces, from the moist lining of a water pipe to the hard enamel of our teeth. While often associated with wet environments, biofilms can also adapt to less moist conditions, revealing their resilience and versatility. In this article, we’ll explore what biofilms are, where they’re found, the health concerns associated with them, and how to control them in building water systems. Definition of biofilm Biofilms are composed of different types of microorganisms, including bacterial and fungal species, that grow on and stick to the surface of a structure. A biofilm may cover natural surfaces, like teeth, or manufactured surfaces, like water pipes or water storage systems. The microorganisms that make up biofilm can be in different states, including actively multiplying, dormant, or simply associated with the biofilm structure. They can also exhibit varied phenotypes, including differences in growth rate, gene expression, and resistance mechanisms. Formation of biofilms The microorganisms in biofilms are often embedded in a self-produced matrix of extracellular polymeric substances, which provides structural support and protection. This matrix contains living and dead cells and resists antimicrobial agents like sterilants, disinfectants, and antibiotics, shielding the microbial cells within. Where biofilms are found “Wet” biofilms typically develop in aqueous environments, including natural bodies of water like rivers and oceans, as well as manufactured surfaces like water pipes, storage tanks, and wastewater treatment facilities. “Dry” biofilms are found in less moist environments. They can develop on surfaces in healthcare settings (e.g., operating rooms), on skin or food surfaces, and in indoor environments (e.g., HVAC systems). Health concerns associated with biofilms Biofilms can harbor and protect waterborne pathogens, making them more disinfectant-resistant. They are implicated in a wide range of infections, such as urinary tract infections, middle-ear infections, and implant-associated infections. Biofilms can also exacerbate chronic wounds and lung infections in cystic fibrosis patients. Bacteria in biofilms are often more resistant to antibiotics, complicating the treatment of infections. How biofilms affect plumbing systems In plumbing systems, biofilms can reduce water flow, clog pipes, and corrode plumbing materials. They can also degrade water quality by harboring waterborne pathogens and releasing them into the water supply during events that alter water pressure and flow, like nearby construction or water main breaks. Controlling biofilms in building water systems Regular maintenance, routine flushing, and cleaning of pipes can help control biofilms. Some continuous supplemental disinfectants like copper-silver ionization can penetrate biofilms, killing the microbes contained inside. Physical treatments on the incoming water supply, like UV disinfection and sediment filtration, can help prevent microbes and nutrient-containing sediment from entering the building water system and contributing to new biofilm growth. When designing new building water systems, plumbing engineers should implement designs that reduce stagnation and ensure consistent water flow to help prevent biofilms from forming. Biofilms are a common and potentially harmful occurrence in building water systems. Proper maintenance and control can help prevent health concerns associated with biofilms and keep plumbing systems functioning properly. By understanding what biofilms are, where they’re found, and how to control them, organizations can ensure the safety and quality of their building’s drinking water.

Waterborne Pathogens a Growing Concern in US Drinking Water, CDC Report Shows

The Centers for Disease Control and Prevention (CDC) has released a report summarizing waterborne disease outbreaks in the United States between 2015 and 2020. The report Surveillance of Waterborne Disease Outbreaks Associated with Drinking Water includes data voluntarily reported by public health agencies to the CDC through the National Outbreak Reporting System (NORS). Data reported includes the waterborne pathogen implicated, outbreak-contributing factors (i.e., practices and factors that lead to outbreaks), and the setting of exposure (e.g., hospital or health care facility; hotel, motel, lodge, or inn). Outbreaks from drinking water During the surveillance period, 214 outbreaks associated with drinking water were reported, resulting in at least: The report found that 80% of outbreaks were linked to public water systems, including municipal water systems or water systems that serve an institution, camp, park, hotel, or business. The remaining outbreaks were linked to unknown water systems (10%), individual or private systems (8%), and other systems (.9%). Most implicated waterborne pathogen: Legionella Legionella caused 98% of biofilm-associated outbreaks, followed by nontuberculous mycobacteria (NTM) at 1% and Pseudomonas at 0.5%. Over the study period, the number of Legionella-associated outbreaks increased, with Legionella being the most common cause of public water system outbreaks, responsible for 92% of outbreaks, 97% of hospitalizations, and 97% of related deaths. Leading contributing factor: Building plumbing systems Building plumbing systems were the most cited contributing factor type for all biofilm-associated pathogen outbreaks. The most reported building plumbing contributing factors were: Out of 214 reported outbreaks, 183, or 86%, included information on water treatment. Among these outbreaks, 116 (54%) drinking water systems reported using disinfection as a water treatment method, 49 (23%) systems had an unknown water treatment, and 17 (8%) drinking water systems reported having no water treatment at all. Chlorine was the most used disinfection method and was used in 37% of all outbreaks. Chloramine was used in 6% of outbreaks, while the remaining outbreaks either used an unknown water disinfection method or the method was not listed. Most common exposure settings: Hospitals and hotels Healthcare facilities (e.g., hospitals, long-term care, assisted living, or rehabilitation facilities) were identified as the exposure setting in 53% of outbreaks, causing 66% of hospitalizations and 87% of deaths. Legionella was implicated in over half of the healthcare-associated outbreaks, causing 65% of hospitalizations and 85% of deaths. Hotels, motels, lodges, or inns were the second highest exposure setting for outbreaks. They were implicated in 16% of outbreaks, all of which were caused by Legionella. Importance of water treatment and management in preventing outbreaks The CDC report highlights the growing concern of waterborne pathogens in US drinking water. Legionella was identified as the most common waterborne pathogen, causing the majority of biofilm-associated outbreaks and being responsible for the highest number of public water system outbreaks, hospitalizations, and related deaths. Effective water treatment and management of building plumbing systems is critical to prevent outbreaks and ensure safe drinking water in healthcare and non-healthcare settings. ReferencesCenters for Disease Control and Prevention. (2024). Surveillance of Waterborne Disease Outbreaks Associated with Drinking Water — United States, 2015–2020. Morbidity and Mortality Weekly Report | CDC

Legionella Bacteria Water Sampling Methodology

This blog delves into systematic approaches for Legionella water testing, offering valuable insights into best practices and recommendations to ensure the safety of your water. Importance of quarterly Legionella sampling Building water systems are dynamic and influenced by various factors such as usage patterns, maintenance schedules, and seasonal changes in municipal water quality. These complex interactions can significantly impact water chemistry and microbiology, creating an environment where Legionella bacteria can thrive. To effectively manage and mitigate the risk of Legionella growth, it is crucial to implement regular testing protocols. Conducting quarterly Legionella testing is strongly recommended. This comprehensive approach not only captures potential seasonal fluctuations but also serves as a robust strategy to ensure the ongoing safety and maintenance of water systems. By prioritizing regular testing, building owners and operators can proactively address any emerging issues and safeguard the well-being of occupants. Sampling methodology Routine sampling for Legionella should be performed to be representative of the building’s water systems. This may be based on size, number of water systems, high-risk locations, and water usage. There are a few strategies in the industry for sampling for Legionella. One method involves taking at least ten samples. Another would be to sample 10% of outlets in the building. These rules may vary depending on the system’s size, but at minimum, it should include near, mid, and far samples, as well as other representative locations. For larger structures, collecting additional samples to account for variations across different floors, water risers, and loops is advisable. This ensures a comprehensive understanding of the system’s water quality. Following this rule strikes a balance between representative sampling and obtaining sufficient data to make informed water management and maintenance decisions. Distal site positivity rule in healthcare The risk of healthcare-associated Legionnaires’ disease significantly increases when 30% or more of distal hot water outlets, such as faucets and showers, test positive for Legionella bacteria. Conversely, the risk decreases if the percentage of positive outlets falls below 30%. This approach, establishing a distal site positivity rule of 30%, offers an effective and practical indicator of Legionella risk in healthcare facilities. By implementing this rule, facilities can proactively implement appropriate corrective actions based on the positivity level and utilize their water management program to enhance maintenance, monitoring, and diagnostic procedures to ensure the safety and well-being of their patients and staff. These measures will help mitigate the potential spread of Legionnaires’ disease and foster a healthier environment for all. Water sampling services LiquiTech provides water quality testing and diagnostics services on an ad-hoc basis or as an ongoing service when you partner with us. We will help you to proactively identify harmful contaminants in your building’s water system, provide easy-to-understand test results with interpretation and recommendations by certified water safety specialists, and help you navigate the Department of Health and other regulatory agencies with expert guidance.

Keeping Hospitals Safe: A Success Story with Lucile Packard Children’s Hospital

When Lucile Packard Children’s Hospital Stanford opened its doors in 1991, it was met with an unexpected challenge: Legionella bacteria in the building’s water system. Despite the hospital’s best efforts, traditional disinfection methods failed to control the problem, which led to two tragic patient deaths. The hospital turned to LiquiTech and the LiquiTech™ Copper-Silver Ionization System, an environmentally friendly and safe method to control Legionella, was quickly installed. Following the installation, several days of rigorous system flushing, monitoring, and water testing took place until Legionella was no longer detected. For over 30 years, the hospital’s water supply has been completely free of Legionella due to continuous monitoring, predictive services, and collaboration on interventions by LiquiTech. As Michael Zader, the hospital’s Administration Director, points out, “We’ve been waterborne pathogen-free since partnering with LiquiTech in 1991”. This success story emphasizes the importance of embracing innovative solutions when traditional methods fall short and Lucile Packard Children’s Hospital’s mission to keep their hospital environment safe. Read the full case study here.

An Examination of Dead Legs, Water Flow, and Legionella Growth

The relationship between stagnant sections in building water systems, known as dead legs, water flow conditions, and the risk of Legionella, a bacterium that causes Legionnaires’ disease, is more complex and multifaceted than commonly perceived. In this article, we explore these topics in-depth, using insights from scientific studies and valuable industry observations. Understanding dead legs Dead legs refer to the segments within pipes in a plumbing system where water flow is either significantly reduced or non-existent. These stagnant areas of plumbing can become a breeding ground for bacteria and other contaminants that can compromise water quality. The lack of flow hinders proper disinfection, provides favorable growth conditions, and accumulation of contaminants which can lead to health concerns. Water flow and Legionella growth Water flow plays a crucial role in the growth of Legionella bacteria. Liu’s 2006 study examined the impact of different flow conditions, such as turbulent, laminar, and stagnant, on Legionella growth. Interestingly, the research found that turbulent flow conditions promoted the most prolific growth of Legionella, while stagnant conditions, often associated with dead legs, showed the least growth. The study hypothesized that turbulent conditions increased oxygen and nutrient availability, leading to the proliferation of biofilm and Legionella. Additionally, Lehtola’s 2006 study revealed that flowing water supported bacterial growth more than stagnant conditions, contrary to common belief. Moreover, Sidari’s 2004 research challenged the widely held belief of a direct link between dead legs and Legionella, as the removal of dead legs did not result in a negative Legionella test. These findings highlight the intricate relationship between water flow and Legionella growth. Dead legs in plumbing and Legionella The presence or absence of dead legs is not a reliable predictor for Legionella. While dead legs can negatively impact water hygiene and quality, they may not directly promote Legionella colonization in building water systems. They may, however, indirectly contribute to Legionella growth and risk of disease occurrence. Stagnant water in dead legs can serve as a potential nutrient source and a refuge for Legionella under specific conditions. Dead legs can also create low water flow areas, decrease disinfectant levels, allow the tempering of water, and increase organic load and sediment accumulation which all may increase the likelihood of Legionella colonization. Due to pressure changes in water systems, dead legs may also contaminate or impact the entire water system. Therefore, while a dead leg alone may not reliably predict Legionella, they should still be considered a potential risk factor and addressed in water management strategies to minimize the risk of Legionella growth and transmission. Emphasizing comprehensive understanding There’s merit in maintaining high water hygiene and quality standards, however, a comprehensive understanding of the actual factors leading to Legionella growth is crucial. While a dead leg can be a contributor to Legionella growth, there are other factors such as water flow that could potentially impact Legionella growth, so it’s important to take a holistic approach and look at the entire building water system. References Liu 2006: Effect of flow regimes on the presence of Legionella within the biofilm of a model plumbing system Lehtola 2006: The effects of changing water flow velocity on the formation of biofilms and water quality in pilot distribution system consisting of copper or polyethylene pipes Sidari 2004: Keeping Legionella out of water systems

Understanding Heterotrophic Plate Count (HPC) Bacteria in Water Systems

Heterotrophic Plate Count (HPC) bacteria are naturally occurring organisms commonly found in water systems. While their presence is not unusual, HPC bacteria are not regulated or routinely monitored as contaminants in drinking water due to their high variability and typically elevated concentrations. HPC bacteria and human health The presence of HPC bacteria in drinking water is a common occurrence. However, it is important to note that these bacteria do not pose direct hygienic (disease-related) significance. Extensive research conducted by experts in the field consistently fails to establish any correlation between HPC bacteria concentrations in drinking water and threats to human health. These findings provide strong evidence that consuming water with HPC bacteria does not jeopardize our well-being. Nonetheless, the detection of HPC bacteria in a drinking water system can serve as an indicator of potential underlying issues. These issues may include inadequate treatment, poor maintenance of the distribution network, or elevated contamination of water bearing equipment. It is crucial to ensure the proper monitoring of water quality and take prompt corrective actions when necessary. While HPC bacteria themselves are not harmful to humans, changes in HPC concentrations may indicate changes in water quality. Therefore, it is essential to remain vigilant in evaluating complex microbial systems. HPC bacteria and Legionella Heterotrophic plate count bacteria and Legionella are bacteria that are commonly found in water sources. Legionella is a genus of bacteria that can cause Legionnaires’ disease, a severe form of pneumonia. HPC bacteria, on the other hand, are a group of bacteria that are commonly used as indicators of water quality. Though high levels of HPC in water systems can serve as an indicator of elevated microbial activity, it is not an indicator for Legionella itself. Monitoring and controlling the levels of HPC bacteria can help understand changes in water quality that potentially could impact the risk of Legionella contamination and subsequent health risks. Role of HPC monitoring in water treatment HPC monitoring plays a vital role in evaluating the effectiveness of municipal water treatment processes. Water providers strive to achieve HPC levels below 500 colony forming units per milliliter (cfu/mL) after treatment to minimize any potential interference with culture-based coliform testing, ensuring accurate and reliable results. With advancements in testing methods, these innovative approaches have successfully mitigated elevated HPC concentrations, thus eliminating any potential impact on coliform test outcomes. Variability of HPC concentrations HPC concentrations vary significantly across different water systems. Comparisons between various sources, such as New Jersey drinking water systems, dental water lines, hospital hot water, and Michigan lakes, highlight the diverse ranges in HPC presence. Water Source HPC (cfu/mL) Reference NJ drinking water system 320 to 1,000,000,000 LeChevallier et al., 1987 Michigan lakes 3,000 to >100,000 Jones et al., 1991 Tuscon, AZ tap water >3,000 Pepper et al., 2004; Chaidez and Gerba, 2004 Apartment building 300–300,000 Bagh et al., 2004 Administration building hot water 24,700–144,000 Sheffer et al., 2005 Hospital hot water 60,000 Sheffer et al., 2005 Dental water lines >3,000 Rice et al., 2006 Research building 16,000 (average) Siebel et al., 2008 New university building >10,000 Nguyen et al., 2008; Nguyen et al., 2012 Hospital hot water 8,000–27,000 Zhang et al., 2009 Hospital hot water 2,900 (average) Duda et al., 2014 New office building 1–100,000 cfu/cm2 (biofilm) Inkinen et al., 2014 Commercial buildings 3 – 2,100,000 Pierre et al., 2019 Case Study: Managing HPC bacteria challenges A case study from a California hospital in 2016 demonstrates the practical management of HPC bacteria. While preparing to open a new patient tower, the hospital found bacteria levels exceeding state and federal EPA limits in the building water system, necessitating intervention. By implementing copper-silver ionization to continuously disinfect the water system and sediment filtration to remove incoming sediment, the hospital successfully controlled bacterial levels and reduced corrosion damage to the plumbing system. While HPC bacteria are common in water systems, they do not pose a significant health threat nor serve as reliable indicators of other waterborne pathogens. Routine HPC monitoring primarily serves to track changes in water quality and treatment efficacy, rather than for health risk assessments. References Allen 2004: Heterotrophic plate count bacteria—what is their significance in drinking water? Duda 2015: Lack of correlation between Legionella colonization and microbial population quantification using heterotrophic plate count and adenosine triphosphate bioluminescence measurement Pierre 2019: Water Quality as a Predictor of Legionella Positivity of Building Water Systems

Legionella and Waterborne Pathogens 101 for Plumbing Engineers

Successful plumbing engineering involves the comprehensive understanding and meticulous control of waterborne pathogens, with a particular focus on Legionella. These harmful pathogens can infiltrate building water systems through various means, such as contaminated water sources or inadequate water treatment. To effectively mitigate the risk of Legionella and other waterborne pathogens, plumbing engineers must possess in-depth knowledge of the specific characteristics of these microorganisms, their transmission routes, and the factors that contribute to their proliferation. By implementing robust water management strategies into their system designs, plumbing engineers play a critical role in safeguarding public health and ensuring the safety of building occupants. Understanding Legionella Legionella is a gram-negative bacterium belonging to the Legionellaceae family, which encompasses more than 60 species and serogroups. Among these, approximately half have been linked to various diseases. Notably, Legionella pneumophila is responsible for over 90% of reported cases of Legionnaires’ disease, a severe form of pneumonia that is contracted through the inhalation and aspiration of water droplets. Legionella growth in building water systems Legionella, a bacterium found naturally in surface and groundwater sources, typically exists in low concentrations in the source water. Legionella and waterborne pathogens can withstand municipal treatment processes and proliferate within building water systems that provide suitable growth factors. Legionella exhibits growth within a specific temperature range, temperatures commonly found in building water systems. Studies show elevated temperatures may reduce the potential for Legionella growth, however, it’s important to consider the impact of factors such as scale, biofilm, and water quality in buildings, as these factors may impact the effectiveness of temperature on Legionella and pathogen growth. Impact of biofilms Biofilms, which are complex communities of microorganisms, consist of cells that adhere to each other and often to a surface. These intricate structures can harbor both pathogenic and non-pathogenic bacteria, creating a diverse and dynamic ecosystem. By providing a protective shield, biofilms enable bacteria to withstand physical forces and disinfection measures, making them resilient and persistent. Moreover, biofilms serve as an ideal breeding ground for bacterial growth, amplification, and recolonization, perpetuating their presence and potential impact. Factors increasing risk Several factors contribute to the increased risk of Legionella and other waterborne pathogen outbreaks in buildings. These factors include the design of complex plumbing systems, which can create stagnant water areas that promote bacterial growth. Additionally, warm water environments provide an ideal breeding ground for pathogens, while increased water age further allows for the accumulation and proliferation of harmful bacteria. Moreover, low disinfection residual levels in the water supply can fail to effectively eliminate these pathogens. It is important to note that construction and renovation events in buildings can introduce additional vulnerabilities, disrupting the plumbing system and potentially exacerbating the risk of outbreaks. Sediment risk and damage Sediment buildup in plumbing systems is an additional risk factor. Sediment can accumulate over time, creating an environment that supports the growth of Legionella and other bacteria. Moreover, sediment can cause corrosion and damage to plumbing equipment, further increasing the risk of bacterial growth and system failure. Methods of Legionella reduction Engineers play a crucial and essential role in managing and reducing the risk of Legionella. By deepening their understanding of the impact of water quality on piping systems and considering Legionella risk during the design phases of building water systems, engineers can effectively implement comprehensive strategies to minimize the risk of Legionella outbreaks. The ASHRAE Standard 188, a widely recognized industry standard, establishes minimum requirements for Legionella risk management in building water systems. This standard provides clear direction and specific requirements for designing and maintaining building water systems that are safe and compliant. By adhering to these guidelines, engineers can ensure the health and well-being of building occupants while effectively mitigating the risk of Legionella contamination. For plumbing engineers, it is crucial to comprehend and regulate waterborne pathogens, such as Legionella. By implementing engineering solutions and performing risk assessments, the potential risk these pathogens pose to water quality and occupants of a building can be greatly diminished.